Pliers might seem like one of the most ordinary tools, but they play an indispensable role in both everyday life and professional work. Whether for home repairs or specialized automotive maintenance, pliers are an essential tool. Especially in the B2B foreign trade sector, offering high-quality, customizable pliers not only meets diverse needs but also helps clients increase efficiency. In this guide, we’ll delve into the principles, classifications, materials, and how to choose the right pliers, helping you understand the true value of this simple yet powerful tool.

The Basic Principle of Pliers

The core purpose of all hand tools is to increase efficiency, and pliers are no different. The working principle of pliers is based on the lever mechanism, which transforms a small external force applied to the handles into a larger clamping or cutting force at the jaws. This design allows pliers to grip or cut objects effectively. By optimizing the length of the handle and the position of the pivot, pliers offer maximum efficiency with minimal effort.

Lever Principle and Force Arms

To generate a larger external force, the design of pliers pays close attention to the balance of the lever. The longer the distance from the handle to the pivot, the greater the force that can be applied at the jaws, leading to increased clamping or cutting force. Conversely, the shorter the distance from the jaw to the pivot, the more precise the cutting action. This design not only makes the pliers easier to use but also ensures they perform efficiently when handling different materials.

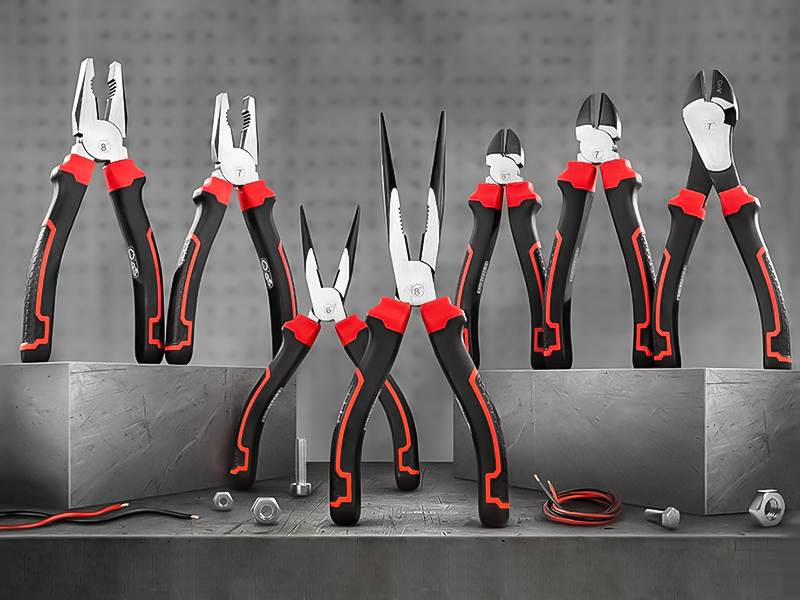

Classification of Pliers

Pliers can be categorized into three primary types based on their functionality:

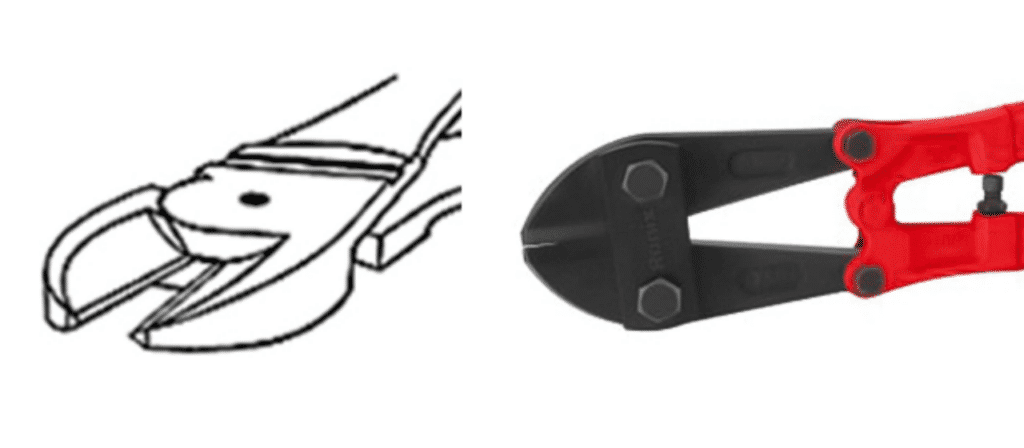

- Cutting Pliers: Primarily used for cutting and trimming materials such as wires, metal rods, etc. Common examples include diagonal cutters, heavy-duty diagonal cutters, and wire cutters.

- Gripping Pliers: Designed to grip objects, helping secure materials during work. Examples include flat-nose pliers, long-nose pliers, and pipe wrenches.

- Combination Pliers: These versatile tools can be used for both gripping and cutting. They are ideal for a wide range of tasks.

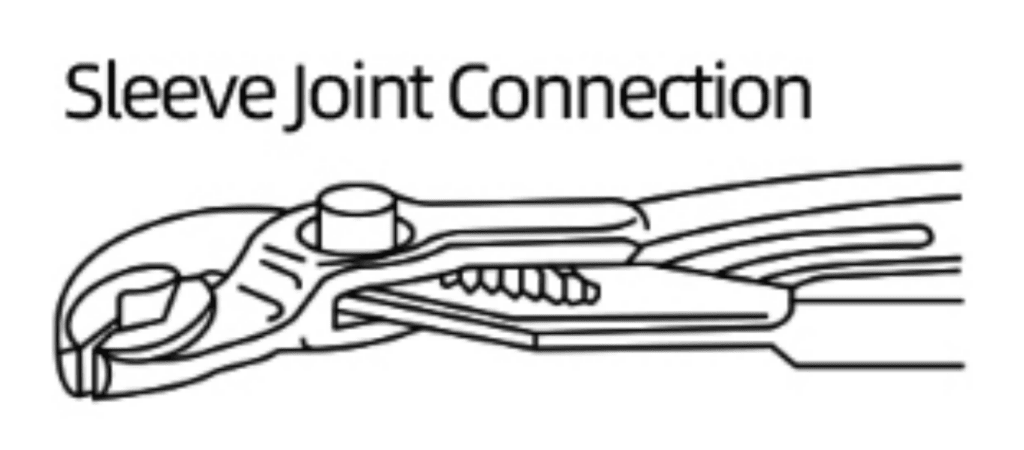

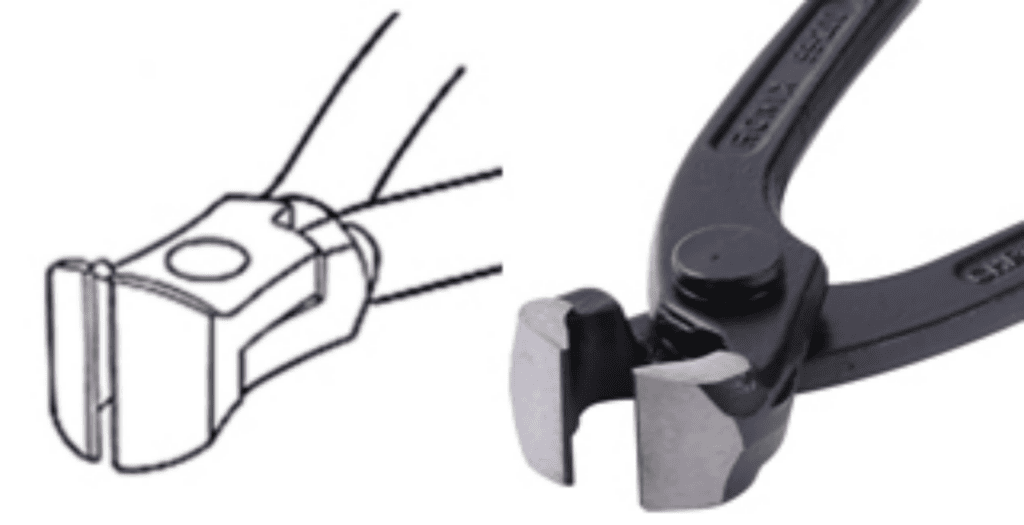

Diagram and Structural Analysis of Pliers

- Handle: Designed ergonomically to ensure comfort and safety while gripping.

- Pivot: The central connection point of the pliers. It must operate smoothly without any looseness to allow easy opening and closing with one hand.

- Jaws: The working part of the pliers, precision-engineered for gripping or cutting, ensuring sharp cutting edges and a precise fit.

Material Selection and Rivet Design for Pliers

The material choice for pliers is crucial for their durability and performance. Pliers are typically made from either alloy steel or non-alloy tool steel. For most pliers, medium-carbon tool steel (with 0.45% carbon content) is commonly used, while heavy-duty pliers are made from high-carbon tool steel or alloyed materials such as chromium and vanadium.

Vivanstar Tips: Maintenance and Longevity of Pliers

Regularly oiling the polished surfaces and pivot points (such as with DW-40) can help maintain the pliers in optimal working condition, extending their service life.

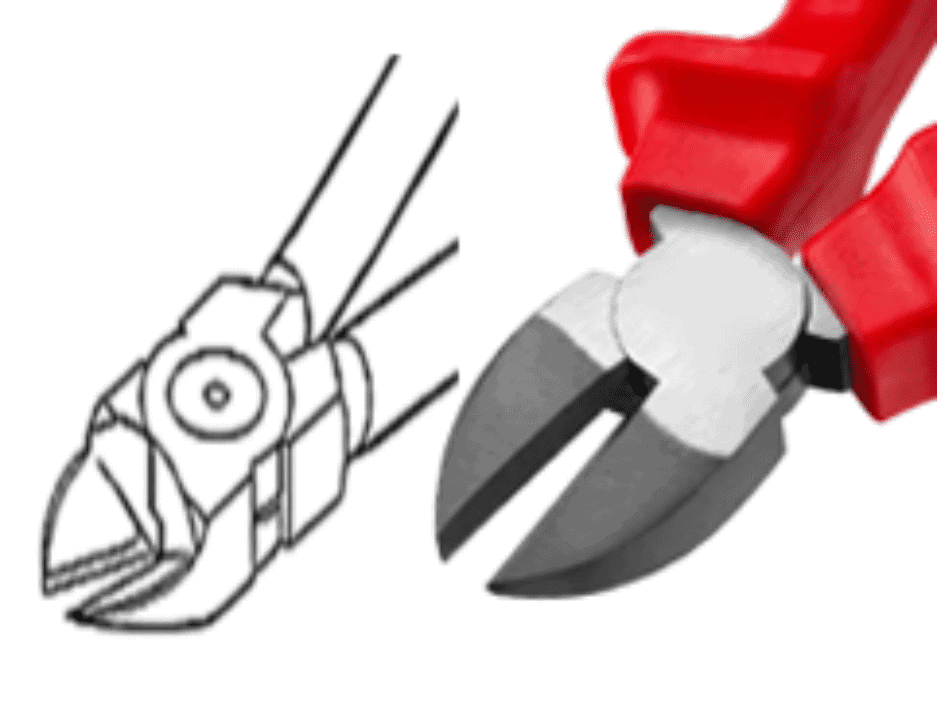

Common Cutting Edge Shapes and Applications

Different cutting needs require specific edge designs. Here are the common cutting methods and their applications:

- Diagonal Cutting: Ideal for cutting a variety of wires and metal strands.

- Center Cutting: Offers a stable cutting angle, perfect for precise cuts, such as for electrical wires.

- Top Cutting: Suitable for angled cuts or flush cuts for wires.

Customization and Low MOQ Services for Pliers

For the B2B market, offering customizable pliers is a key strategy to satisfy diverse customer requirements. Vivanstar provides not only a wide range of standard pliers but also custom pliers solutions to meet specific needs. Whether for automotive tool repair or industrial applications, we can offer tailor-made pliers that fit the exact requirements of your business.

In addition, we offer flexible low MOQ (minimum order quantity) services to accommodate clients of all sizes. Whether you are a small business starting out or a large-scale distributor, we provide solutions that align with your order volume, ensuring a smooth and efficient procurement process.

How to Choose the Right Pliers

Selecting the right pliers depends on the material and working environment. For example, in the automotive repair industry, pliers need to be more durable and capable of handling tougher cutting tasks, making high-alloy steel pliers a good choice. For automotive tool wholesalers, offering a variety of pliers types and sizes is crucial to meet the needs of different repair tasks.

Additionally, custom pliers services greatly enhance the selection process. Especially for industries with specific requirements, such as precision equipment repairs or heavy machinery maintenance, customized tools can provide more professional solutions.

Selection Criteria:

- Material Strength: The material of the pliers determines its durability and cutting capacity. High-carbon steel pliers are suited for heavy-duty tasks, while alloy steel pliers are ideal for precision work.

- Handle Design: Ensure the handle design is ergonomic, reducing fatigue during prolonged use.

- Cutting Capacity: Different types of pliers are suitable for various materials and cutting methods. Choose based on the specific needs of your job.

Improve Work Efficiency with Vivanstar

Vivanstar, as a leading manufacturer of hand tools, is committed to providing high-quality pliers to global customers. We not only offer a wide range of pliers types but also support custom pliers services tailored to meet specific client needs. With our advanced manufacturing processes and strict quality control, Vivanstar pliers are designed to help customers in automotive repairs, home renovations, and industrial equipment maintenance enhance their work efficiency.

Our products are suitable for wholesalers and distributors, and we support low MOQ customization, making it easier for businesses of all sizes to source the right tools. Whether you’re looking for standard pliers or customized solutions, Vivanstar provides the right tools for the job.